Auto-Print for Oral Solid Medications

Oral Solid Unit Dose Pill Packing Machine: Complete Packaging System

MPI’s Auto-PrintTM Unit Dose Packaging System is a complete primary packaging and barcoding solution for oral solid medications. This durable, high-performance system simplifies maintenance and operation, helping pharmacies decrease costs, increase efficiency, and reduce medication errors.

- Auto-Print SUPERTHERM® Thermal Paper: Smudge-free, fade-resistant material allows for direct thermal printing.

- Auto-Print SUPERCEL® Film: Provides clear visibility of medication, also available in six other colors for identification of controlled medications or color coding medications by expiration date.

- Proprietary to MPI’s Auto-Print system, prints barcode and medication information directly on the SUPERTHERM® side.

- Smudge-free and fade-resistant for easy scanning and compliance for repackaging of medication.

How it Works: Pill Packer in Action

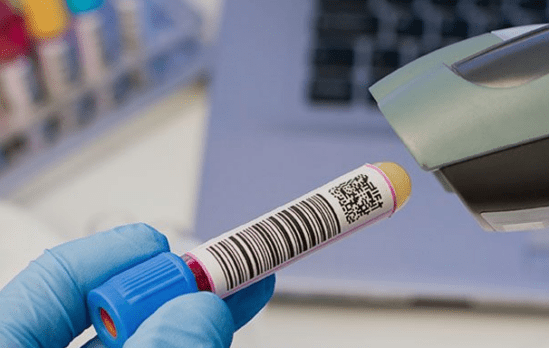

This machine packages and barcodes tablets or capsules at a speed of up to 60 packages per minute. Using MPI-certified packaging materials designed specifically for MPI’s Auto-PrintTM, the multi-layered composition of these consumable materials combined with a built-in low sealing temperature process assures that all medication will be adequately protected from external environmental effects such as light or moisture. This machine provides a clear, legible print of all medication information including a scannable barcode.

The materials and manufacturing processes are FDA-registered, food grade, and meet USP Class A and B standards for medication packaging. As per U.S. Pharmacopeia guidelines, a one-year beyond-use date (BUD) or the product’s remaining expiration date, whichever is shorter, can be applied.

Decrease Costs & Increase Production Line Efficiency

Packaging bulk medication into unit dose is more cost-effective than buying products pre-packaged from the manufacturer. The high speed of 60 packages per minute eliminates the need for manual packaging and sorting, thus freeing up pharmacy staff to focus on other tasks. Accurate inventory control and maintenance of stock levels can be maintained through the use of Pak-EDGE® software.

Reduce Error

The Auto-PrintTM machine is an excellent choice to reduce or eliminate medication errors for many reasons such as:

- Barcode and Scan Check: Scanning bulk bottle before packaging verifies the proper drug.

- Barcode Verifier: Scanning each package after packaging the unit dose container assures that the barcode can be accurately scanned at the bedside.

- Tall-Man Lettering: Helps reduce “look alike, sounds alike” errors.

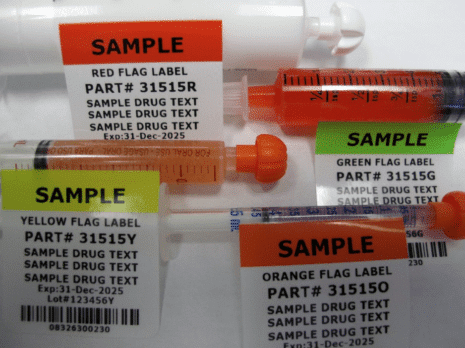

- Colored Materials: 6 different colors of Auto-Print SUPERCEL® are available for color-coding of expiration dates and controlled medications.

- Product Recall: In the event of a product recall, Pak-EDGE software can easily trace the packaged product, allowing the pharmacist to take immediate corrective action to remove the medication from inventory.

- Unit Dose Improves Patient Safety: Taking large quantities of medication from manufacturers in pill bottles and dividing them into individually packaged doses improves safety, and better adheres to prescribed dosages.

Product Gallery

Contact MPI Today for Personal Assistance

MPI’s Drug Master File provides speed-to-market regulatory and technical support related to our packaging components for medical and pharmaceutical market clients