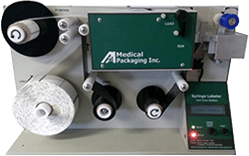

Auto-Wrap® Syringe Labeling System

Auto-Wrap® Syringe Labeling Machine: Syringe Labeling Simplified

MPI’s Auto-Wrap® Syringe Labeling System automates the process of labeling syringes and assists in increasing throughput while reducing repetitive stress injuries (RSI), all while ensuring accurate and consistent labeling for enhanced patient safety and regulatory compliance.

Automatic Syringe Labeler

This semi-automatic solution produces a printed self-adhesive label and automatically wraps it around a syringe in one single motion at a high speed of up to twenty (20) syringes per minute.

MPI’s Auto-Wrap Syringe Labeling Equipment can accommodate any type of oral or injectable syringe from ½ mL up to 60 mL without any need for adjustment or changing of parts. The open-face compact design allows for easy loading of label stock and access to all controls.

Optimize The Syringe Labeling Process

- An independent time-motion study conducted on MPI’s Auto-Wrap Syringe Labeling System concluded that significant time savings can be achieved through automation versus manual wrapping—save anywhere from 1 ½ minutes to 2 ⅔ minutes per batch of 25 syringes.

- This saves about 4 cents per label.

- The system’s high precision and high-speed performance ensure consistent label placement, reducing downtime and enhancing overall productivity.

MPI Exclusive Materials

- To assure maximum adhesion and legibility, MPI’s Auto-Wrap Syringe Labeling System requires the use of label media developed by MPI in conjunction with MPI’s Pak-EDGE® UD Barcode Labeling Software, which is included with the labeling system.

- Flagged and tacked adhesive labels are offered with print areas ranging from 1″ to 1.5″.

- Various color flag labels can be used with this machine for various purposes, such as:

- Identifying pediatrics

- Variants/doses of a drug

- Storage conditions

Technical Specifications

- Size: 17.5″ W x 7.5″ D x 11.0″ H

- Weight: 25 lbs.

- Power: 115VAC 50/60Hz or 230VAC 50/60Hz

- Safety: CE, NRTL (MET) US, C

- Hardware Requirements: Computer with Windows® 10 or higher, 10 GB hard drive space, 8 GB RAM, available USB ports, desktop or network printer for reports, Internet access.

- Software Requirements: Pak-EDGE® UD Barcode Labeling Software (provided with packaging system).

- Material Requirements: Requires the use of MPI label media to assure maximum adhesion and legibility.

- Space Requirements:

- Sturdy and level countertop, height of 36″ or higher for comfortable working conditions.

- Clearance above the counter should be 24″ minimum.

- More than 4′ of counter space is recommended for the labeling station.

- The Auto-Wrap Syringe Labeling System requires one (1) 120V outlet.

Choose MPI for Your Syringe Labeling Needs

- MPI’s dedication to providing innovative and high-quality solutions is at the core of the Auto-Wrap® Syringe Labeling System.

- Built with a modular design, stainless steel components, and a user-friendly interface, it supports the healthcare and pharmaceutical industries by offering:

- Reliability

- Precision

- Minimal downtime

Compliance & Efficiency

- Our labeling equipment ensures safe and accurate syringe labeling while maintaining compliance with all regulatory standards.

- With a focus on enhancing the labeling process for syringes, MPI stands as the leading choice for healthcare and pharmaceutical applications requiring fast, efficient, and durable solutions.

Contact MPI Today for Personal Assistance

If you would like more information about our company, our medication packaging and labeling machines and MPI-certified consumable materials, and the custom solutions we provide, click below to contact us today.