Products

Products: Medical Packaging Inc., LLC

Unit Dose Packaging & Pharmacy Barcoding Solutions for Hospital and Health-System Pharmacies

For over 50 years, Medical Packaging Inc. (MPI) has been a leading provider of unit dose repackaging equipment and pharmacy barcoding solutions, supporting hospitals, health systems, long-term care facilities, and more with reliable, cost-effective automation. MPI’s packaging portfolio supports a wide range of unit dose packaging and labeling solutions used in hospitals, acute care facilities, long-term care pharmacies, specialty pharmacies, and pharmaceutical companies.

Our medication packaging equipment includes unit dose prepackaging machines for oral solids and liquids,, barcoding and labeling solutions for syringes, ampoules, vials, etc. . These solutions help health care providers manage complex dosage forms, improve medication adherence, and standardize packaging across the organization.

We offer packaging systems, materials, and software that help reduce medication errors while ensuring regulatory compliance and product safety. Our pharmaceutical packaging machinery features compact design and innovative technology that supports quality control throughout the manufacturing process and across the entire packaging life cycle.

Medical Packaging Inc., LLC delivers efficient packaging solutions to customers worldwide ranging from hospital pharmacies and long-term care facilities to pharmaceutical industry manufacturers and contract drug administration sites. MPI supports the pharmaceutical sector with equipment that meets specific packaging requirements and integrates with existing production lines.

Oral Solid Medication Packaging

Efficient and Flexible Packaging Solutions

Medical Packaging Inc. (MPI) delivers adaptable systems that streamline unit dose packaging for oral solid medications in hospital, pharmacy, and other healthcare settings. Our semi-automatic machines handle a variety of dosage forms while supporting medication adherence programs and clear patient instructions at the point of care. By reducing manual handling and maintaining consistent seal quality, these solutions shorten medication delivery time, strengthen patient safety, and make it easier for caregivers to manage complex regimens.

Oral Liquid Medication Packaging

Reliable, Cost-Effective Solutions for Liquid Unit Dose Packaging

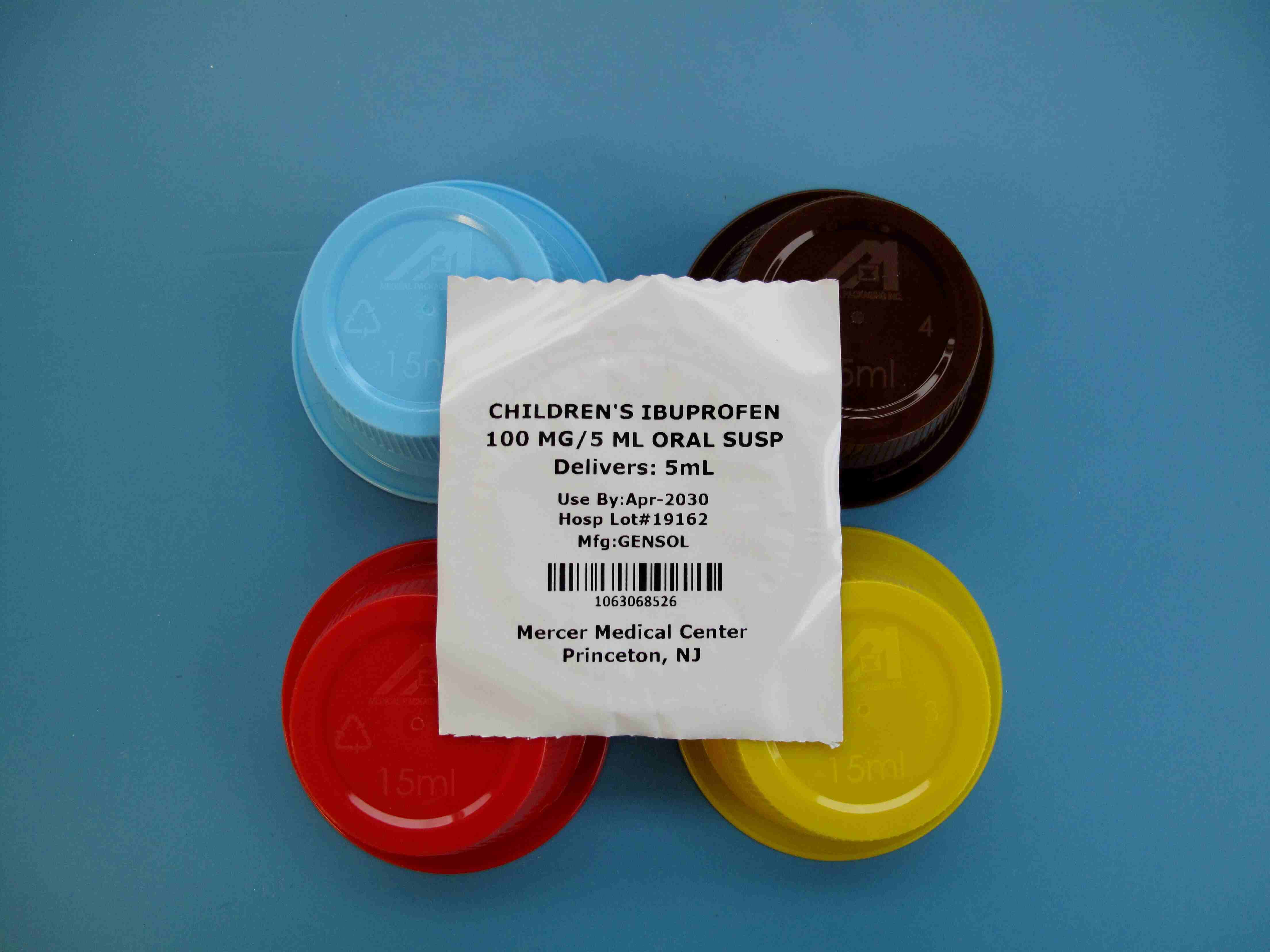

MPI offers a range of advanced packaging systems designed to deliver accurate, contamination-resistant unit doses of liquid medications. Engineered for safety, precision, and ease of use, our solutions help protect liquid drug integrity while improving dosing accuracy across a wide range of dosage forms for human use.

Whether in a pharmacy or manufacturing facility, our liquid unit dose systems are built to reduce packaging costs, boost operational efficiency, and minimize the risk of medication errors—supporting better outcomes across the pharmaceutical supply chain. By combining high-quality packaging materials with intuitive controls, these systems give health care providers confidence in every medicine pack they dispense.

For organizations evaluating new medical packaging investments, MPI supports risk assessments around safety concern, environmental impact, and packaging life cycle to ensure the chosen solution supports sustainable, compliant, and patient-focused operations.

Overwrapping Solutions for Enhanced Protection

Streamlined Over-Wrap Packaging for Efficient Storage and Distribution

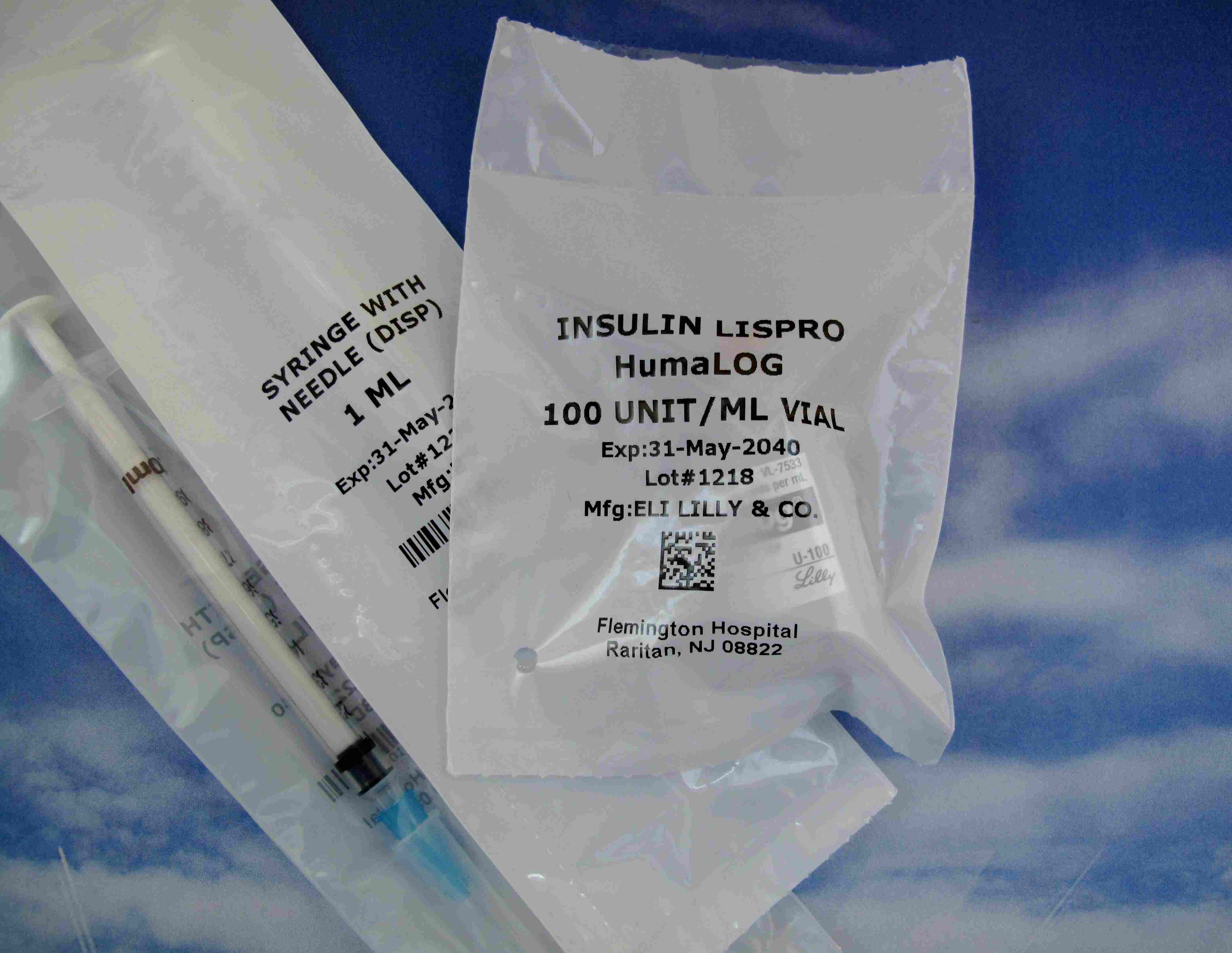

MPI’s over-wrap packaging systems offer a complete solution for bagging, labeling, barcoding, and sealing prescription medications and related accessories. These systems are ideal for secondary packaging, combining cartons or unit dose strips into a single pack for efficient inventory management and distribution.

Designed to enhance organization, protection, and inventory management, our systems support improved storage and streamlined workflows. For high-volume facilities, joint pack and multi-product overwraps help consolidate shipments, reduce handling, and improve product safety during transport.

For facilities using centralized robotic distribution, we also offer an overwrapping solution fully compatible with automated systems—ensuring maximum efficiency, consistent sealing, and integration across your pharmaceutical operations.

Labeling Solutions

Automated Pharmacy Labeling Solutions for Safety and Efficiency

MPI’s pharmacy labeling systems empower pharmacists and healthcare professionals to create precise, high-quality labels and barcodes for syringes, unit dose strips, IV bags, and other pharmacy accessories. These automated labelers support necessary information such as drug information, dosage forms, administration route, patient information (data not stored within the software), and product safety warnings.

By automating the labeling process, our solutions help pharmacies complete more orders in less time, improve organization, and enhance overall workflow efficiency. Designed with staff safety in mind, these systems also reduce the risk of repetitive stress injuries, supporting a more productive and ergonomic pharmacy environment.

Pak-EDGE® UD Barcode Labeling Software

Powerful, Customizable Labeling Software

Every new MPI medication packaging system purchase comes equipped with a license for Pak-EDGE® UD Barcode Labeling Software Version 2.0—an easy-to-use application designed to streamline label and barcode creation. This software brings together medical packaging, configuration, and barcode management into a single, efficient workflow.

Pak-EDGE® 2.0 features a modern user interface and integrates seamlessly with all MPI packaging systems. With tools like comprehensive label designer, drug profile library, and import functions, it empowers pharmacies to create precise, compliant labeling for medication and accessories—all while enhancing efficiency and workflow.

Hospitals, long-term care pharmacies, and specialized pharmaceutical industry partners rely on Pak-EDGE® to track product life cycle data and maintain consistent label formats across multiple locations.

Why Choose MPI’s Pharmaceutical Packaging Equipment

With over 50 years of experience, Medical Packaging Inc., LLC (MPI) delivers pharmaceutical packaging machines that solve key challenges in the pharmaceutical industry—reducing errors, improving efficiency, and ensuring regulatory compliance. Our packaging systems and MPI-certified materials help healthcare providers streamline operations and enhance product quality.

MPI offers sustainable solutions that simplify the packaging process, support supply chain flexibility, and meet the unique demands of high-volume production, custom formulations, and patient-specific services.

MPI understands that health care providers must balance medication adherence, environmental impact, and operational efficiency. That is why our packaging options are designed to support both regulatory expectations and internal safety concern reviews.

For pharmaceutical companies and contract manufacturers, MPI’s FDA-accepted Type III Drug Master Files (DMFs) and documentation help simplify regulatory submissions and provide a strong technical foundation for global applications. Our team can provide the necessary information to support moderator analysis, internal audits, and quality system reviews related to your packaging operations.

Transform Your Packaging Operations Today

Eliminate inefficient manual packaging and reduce compliance burdens with MPI’s pharmaceutical packaging equipment. Our configurable systems integrate into existing pharmacy and manufacturing workflows while supporting regulatory compliance, patient safety, and medication adherence.

From acute care hospitals and health systems to long-term care facilities, retail pharmacies, and pharmaceutical industry manufacturers, MPI helps organizations move from manual processes to reliable, automated packaging that supports patient care.

Contact Medical Packaging Inc., LLC today to learn how our acute care and pharma packaging solutions can deliver measurable improvements in efficiency, compliance, and patient safety across pharmaceutical companies, hospitals, and pharmacies. Our experts can walk through your current packaging options, analyze your secondary packaging and labeling needs, and recommend solutions that align with your operational goals.

Experience proven pharmaceutical packaging machinery for modern healthcare operations.