Drug Master File Benefits: Accelerating FDA Approval for Packaging Components

Drug Master File Benefits: Accelerating FDA Approval for Packaging Components

The Short Answer: A Drug Master File (DMF) is a confidential submission that allows a packaging supplier (the DMF holder) to provide detailed manufacturing and technical information directly to the FDA. By referencing a DMF instead of recreating the same data, pharmaceutical companies can streamline new drug applications and other regulatory filings in the United States.

A DMF is a master file the FDA maintains that contains complete information on facilities, raw materials, manufacturing procedures, and packaging components used in a drug product. For packaging and unit dose systems, the supplier submits this information once in an electronic format. When a pharmaceutical company files a new drug application or investigational new drug application, it can cross reference the DMF number rather than submitting the supplier’s confidential information. The regulatory authority gains the necessary information for drug evaluation, the DMF holder protects proprietary processes, and the applicant reduces documentation workload and review delays.

We’ll cover the main DMF types, what belongs in a Type III packaging DMF, and how DMFs help streamline FDA review for packaging components.

Types of DMFs Related to Packaging

In the FDA’s DMF system, a single master file can be cross-referenced by multiple applicants, connecting the FDA as the regulatory authority, the DMF holder as the supplier, and the pharmaceutical company through one confidential source of technical information.

The FDA recognizes several DMF types that may intersect with packaging and related components:

- Type II – Drug substances and intermediates.

Covers the drug substance, drug substance intermediates, and certain raw materials used in their preparation. In many cases, this aligns with an active pharmaceutical ingredient or active substance master file that supports the core drug product. - Type III – Packaging materials.

The most relevant category for packaging suppliers, addressing containers, closures, and other drug product contact components such as bottles, blister materials, and unit dose packaging systems used in drug administration. - Type IV – Excipients, colorants, flavors, and essences.

Describes inactive ingredients that support the formulation but do not provide therapeutic effect. These materials can impact compatibility with packaging and overall drug stability. - Type V – FDA-accepted reference information.

Used for additional information the FDA agrees to maintain in master file form, such as technical information or reference data that may apply across multiple applications.

For advanced products in regenerative medicine and gene therapy, DMFs may also be used to document ancillary material and specialized packaging that support manufacturing and drug administration in line with evolving regulatory requirements.

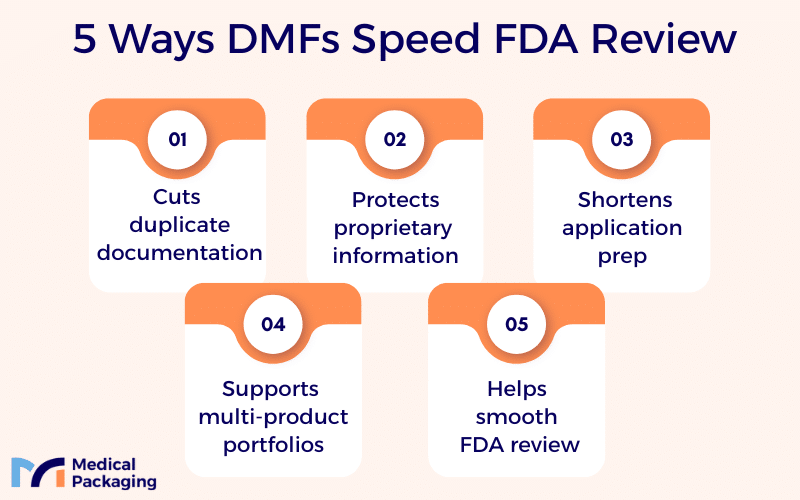

Five Ways DMFs Accelerate FDA Approval for Packaging Components

Drug Master Files create a direct pathway between packaging suppliers and the FDA, reducing documentation for pharmaceutical companies and supporting faster, more predictable review. With packaging technical information captured in a DMF, applicants can focus regulatory affairs work on the drug product and reference a single master file for components.

1. Eliminates Duplicate Documentation

Without a DMF, each pharmaceutical company must request the same technical information—manufacturing procedures, raw materials, and quality data—from every packaging supplier for each new drug application or export application. A DMF centralizes this information with the FDA, allowing multiple applicants to cross-reference a single DMF number. This reduces repetitive document exchange and minimizes administrative burden for both the DMF holder and the applicant.

2. Protects Proprietary Information

Packaging suppliers invest heavily in specialized materials, barrier technologies, and manufacturing methods. Sharing this confidential information with every customer increases intellectual property risk. The DMF system allows suppliers to submit confidential, detailed information directly to the FDA while providing customers with confirmation that packaging meets regulatory requirements. The regulatory authority reviews the technical information independently, so proprietary formulations and processes remain protected.

3. Speeds Up Application Preparation

Preparing a new drug application or abbreviated new drug application requires extensive packaging data. When suppliers maintain current DMFs in an accepted electronic format, applicants can reference that complete information instead of building custom technical packages from scratch. This approach lets regulatory affairs teams advance clinical and manufacturing sections while packaging data is already available for cross-reference.

4. Simplifies Multi-Product Applications

Many pharmaceutical companies and contract manufacturers use the same bottles, blisters, or closures across multiple drug products. A single packaging DMF filing can support an unlimited number of applications by serving as a common technical reference. Instead of recreating packaging sections for each product, applicants reuse the same DMF number, creating efficiency across their broader regulatory strategy and reducing variability in submitted information.

5. Reduces FDA Review Time

When packaging information is embedded separately in every original submission, FDA reviewers must repeat the same technical evaluation for each application. With a DMF, reviewers access an established master file, apply consistent review procedures, and focus drug evaluation on new elements of the application. Well-documented DMFs with regular annual updates often lead to fewer information requests and smoother review for standard packaging components used across multiple products.

What Information Goes Into a Packaging Component DMF?

A packaging component Drug Master File (Type III) provides the FDA with detailed information and technical data showing a material is suitable for drug contact. These submissions typically cover four main areas:

- Manufacturing details

- Material specifications

- Testing and quality data

- Regulatory compliance and maintenance

Together, they give the regulatory body the necessary information to evaluate safety and performance without exposing confidential information to the new drug application holder.

Required Technical Documentation

A Type III packaging DMF typically includes:

- Component description

- What the component is and its role in the drug product or drug administration

- Manufacturing overview

- Manufacturing sites for the DMF holder

- High-level manufacturing procedures and process flow from raw materials to finished component

- Quality management

- Summary of quality and regulatory oversight responsibilities

Material Specifications

This section explains what the component is made of and how it behaves:

- Composition and raw materials

- Base polymers, additives, colorants, processing aids, and any ancillary material relevant to drug contact

- Physical and chemical properties

- Key mechanical, barrier, and stability properties under intended storage and use conditions

Testing and Quality Data

To support regulatory review, the DMF summarizes how performance is verified:

- Analytical methods and validation

- Methods for critical quality attributes and validation summaries

- Representative batch data

- Evidence of lot-to-lot consistency

- Extractables and leachables (as applicable)

- High-level results showing potential migrants from packaging into the drug product remain within acceptable limits

Regulatory Compliance and Maintenance

The DMF also shows how the DMF holder maintains control and keeps information current:

- Quality and compliance framework

- Alignment with applicable Good Manufacturing Practices

- Change control and supplier qualification for critical raw materials

- Ongoing maintenance

- Amendments submitted after the original submission when significant changes occur

- An annual update or annual report confirming the DMF information remains accurate for cross-referenced NDAs, ANDAs, INDs, and export applications

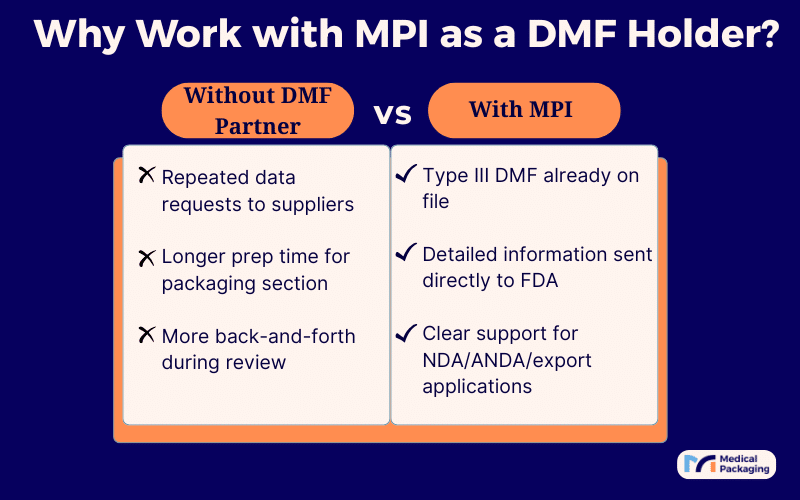

Why DMF-Ready Packaging Partners Matter

Drug Master Files are one of the most practical tools available to pharmaceutical companies navigating FDA approval. Working with packaging suppliers who maintain current DMFs reduces duplicate documentation and testing, lightens the load on internal regulatory affairs teams, and supports more efficient review procedures by the regulatory authority.

MPI’s DMF and Packaging Support

Medical Packaging Inc. LLC (MPI) maintains FDA-accepted Type III Drug Master Files for key packaging materials and understands the specific regulatory requirements facing pharmaceutical companies, contract manufacturers, and repackagers. From unit dose packaging systems for oral solids and liquids to overwrapping and labeling solutions, MPI supports safe, efficient drug administration across hospitals, long-term care, and retail pharmacy settings in the United States.

As a DMF holder, MPI provides detailed technical information, administrative information, and relevant supporting data directly to the FDA, allowing customers to cite the DMF number in their applications instead of rebuilding confidential information from scratch. This reduces documentation burden, promotes consistent regulatory review, and gives teams a packaging partner with a proven regulatory foundation they can rely on.

Connect with MPI to review current DMF coverage, how their master files can be cited in your submissions, and which solutions best support your next approval.

Contact MPI Today for Personal Assistance

MPI’s Drug Master File provides speed-to-market regulatory and technical support related to our packaging components for medical and pharmaceutical market clients