FD-Pharma®

FD-Pharma® Unit Dose Packaging System

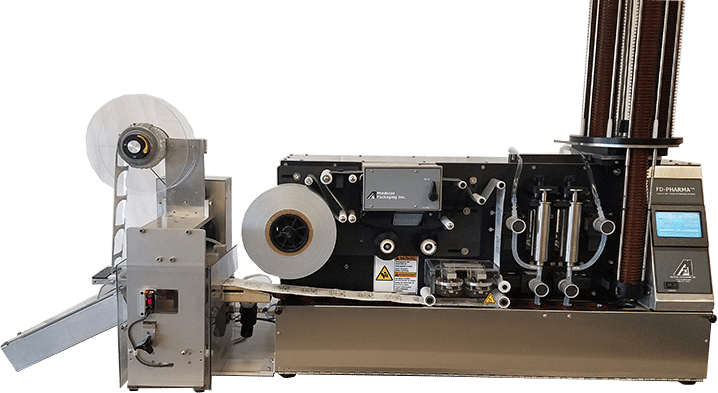

MPI’s FD-Pharma® Unit Dose Packaging System with built-in printing and pumping system is an automated, barcoding packaging solution for unit dose oral liquid medication. FD-Pharma® offers precise liquid dosing, in a convenient unit dose cup. The FD-Pharma® has a small footprint and a small price point, with professional results! Adding the FD-Pharma® to your production equipment portfolio would add liquid cup packaging capability able to address clinical trials, small production and validation runs, and full production mode, all in one machine. The FD-Pharma® is a re-engineered version of our Fluidose® system which has been supplying institutional liquid unit dose packaging to hospital pharmacies worldwide for over 20 years.

Printing

- Integrated label printing system with serialization and standard barcodes.

- No pre-printed label stock is needed; prints on top of lid before filling.

- 300 d.p.i. Thermal Transfer printer with full resin ribbon.

- Includes Pak-Edge® UD Barcode Labeling Software.

Pumping

- Two fully programmable linear drive stepper-controlled pumping stations.

- Uses two 50mL autoclavable stainless-steel syringes for positive displacement.

- Features 2 intake and 2 output pinch valves designed for 50 Dur silicone tubing (check valves optional).

- Fully programmable draw rates, dispense rates, and dwell time via touchscreen interface.

- Customizable syringe, tubing, and valve setup based on product requirements.

Sealing

- Single linear drive sealing station with two seal platens.

- Programmable sealing temperature range: 150°C to 230°C (default 220°C).

- Includes programmable low limit set point and operational temperature warnings for low or over limit as well as damaged thermocouple.

- Programmable seal dwell time, seal rate, and seal pressure via a touchscreen interface.

- Interchangeable parts for different-sized cups (7mL, 15mL, 25mL, and 35mL).

Single Dose Packaging and Labeling Simplified

- MPI’s proprietary packaging materials conform to FDA regulations for use in direct food contact.

- The FD-Pharma® is designed for ease of operation, allowing line technicians to become proficient with minimal training.

- Equipped with a built-in scanner, this advanced machine ensures 100% verification of readable barcodes on unit dose packages.

- Packages 35mL doses at rates of up to 35 per minute and follows all safety standards.

Decrease Costs

- Generates labels on the machine during packaging, eliminating the expenses and waste of pre-printed label lidding.

- Small footprint and affordable price point further reduce costs.

- Offers quick changeovers with minimal cleaning required, resulting in a low cost per dose (CPD).

- Low cost of ownership due to extremely low maintenance costs for both operation and upkeep.

- Adds liquid cup packaging capabilities in clinical trials, small production, validation runs, and full production mode.

Add-Ons

- Barcode Verifier: Scans each package as it leaves the FD-Pharma® conveyor belt to ensure that it has a readable barcode. If an unreadable barcode is detected, the system pauses to allow the user to retry or remove the package.

- Air Rinser: Uses a short burst of air into the cup, directing debris into collection netting before advancing and filling the next cup.

- Die Cut Feature: Optional separately powered module that trims the lidding to the cup’s perimeter, leaving a tabbed section for professional die-cut labeling at speeds up to 23 cups per minute.

Material Specifications

Cups – Single Dose Containers

- High-Density Polyethylene (HDPE).

- Sizes: 15mL (2.0” Rim x 0.78” height), 25mL (2.0” Rim x 1.21” height), 35mL (2.0” Rim x 1.49” height).

- Standard colors: Blue, Red, Yellow, and Amber; custom colors available (minimum purchase required).

- Meets FDA regulation 21 CFR 177.1520 and USP UV light resistance (Stock colors: Red and Amber).

Lidding

- Lidding Width: 2.125”.

- Peelable sealant HDPE lidding and printable PET matte surface.

- Constructed with LDPE and foil layers.

- Complies with FDA regulations for food, beverage, and pharmaceutical industry products.

Machine Specifications

- Size: 37″ L x 14″ W x 18″ H

- Weight: 130 lbs.

- Power: 115VAC, 500VA

- Sealing Temperature: 220°C

- Production Speed: Up to 35 cups per minute

- Filling Volume:

- 3mL (recommended minimum)

- 35mL (recommended maximum to fill line)

- Machine Format: Linear, conveyor, double index.

- Packaging Format: Unit Dose Cup with non-die cut lidding.

- Applications: A pumping system/tubing can be arranged to support a range of fluids of varying viscosities. While designed for oral medications, potential applications are broader.

Die Cut Filling Equipment Module Specifications

- Size: 22″W x 12″D x 24″H (Includes input and output chutes)

- Weight: 40 lbs.

- Power: 115VAC 50/60Hz, 50VA

- Air: 100PSI, 10CFM; 60PSI working

Partner with The Industry Leader

- MPI’s advanced technology minimizes human error, ensuring patient safety across various markets.

- Our efficient packaging solutions streamline the process for liquid products, benefiting the pharmaceutical industry with compliant and precise packaging.

- Dedicated customer service to help implement and maintain packaging machines and products.

Regulatory Compliance and Industry Support

- Our Drug Master File enables MPI to rapidly support customers’ compliance and filing needs within the pharmaceutical packaging industry.

- Meets production line needs of pharmaceutical drug manufacturers and contract drug manufacturing organizations (CDMOs) for FDA-compliant liquid cup packaging.

Contact MPI Today for Personal Assistance

If you would like more information about our company, our medication packaging and labeling machines and MPI-certified consumable materials, and the custom solutions we provide, click below to contact us today.