Auto-Print Plus for Oral Solid Medications

Oral Solid Unit Dose Pill Packing Machine: Complete Packaging System

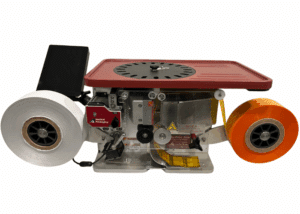

The Auto-PrintTM Plus, the latest oral solid packager, is an advanced unit dose medication packaging system designed for hospitals and healthcare facilities. It provides a compact, user-friendly solution for high-speed medication packaging while prioritizing safety, convenience, and operational efficiency. The system integrates packaging and printing in one modular machine with a significantly smaller footprint than previous models.

How the Auto-PrintTM Plus Pill Packaging Solution Works

Our Next-Generation Medication Packaging System

The machine packages medications in customizable pouch lengths (1” to 2”) and operates at selectable speeds, reaching up to 80 packages per minute. The standard width of each package is 2”. The length of each package can be adjusted to four different sizes (1”, 1.25”, 1.50” and 2.0”) to better accommodate medication size, varying printed label information or to reduce material consumption lowering cost per dose. The machine is rate selectable and can be operated at four speeds to meet the user’s packaging preference.

Powered by Pak-EDGE® UD Barcode Labeling Software, the touch screen control panel provides the interface for setup and daily operations. The machine uses a dual-wheel drive system to pull material evenly while reducing slippage. Sensor feedback and component control ensure accurate packaging and alert the operator to machine status.

Using MPI-certified packaging materials designed specifically for MPI’s Auto-PrintTM Plus, the multi-layered composition of these consumable materials assures that all medication will be adequately protected from external environmental effects such as light or moisture. This machine provides a clear, legible print of all medication information, including a scannable barcode.

Key Features & Technical Specifications

Optimized Technology Components

Display & Interface

- Touchscreen for operation and setup.

- Multilingual support (English, Spanish, French, Portuguese).

- Displays product name, package length, and count of packaged meds.

- Access to advanced parameters like seal temperature and dwell time.

Packaging & Performance

- Adjustable pouch sizes: 1”, 1.25”, 1.5”, and 2”.

- Four selectable speeds (50–80 packages per minute).

- Energy-saving auto-shutoff for heater.

- Single power cord with low energy consumption.

- Compact footprint (approximately 50% smaller than prior models).

- Black feed disks enhance pill visibility.

- Dual-wheel material drive for consistent feed.

Maintenance

- Designed for user-performed preventative maintenance.

- Simple seal pressure dials and slide-out seal block.

- Tool-free O-ring removal.

- Accessible print head and front-removable drive roller.

- Blade replacement assisted by alignment slots.

Additional Enhancements

- Modular design with swappable subassemblies.

- Front-loaded design for easy material changes.

- Fewer components require assembly, ships mostly pre-assembled.

- Safety guard is smaller, easier to operate, and more durable.

Why Upgrade Your Oral Solid Medication Packaging

The Auto-PrintTM Plus unit dose packaging system is MPI’s next-generation packaging system for oral solid medications, packaging up to 80 unit dose packages per minute. The machine is currently available in the United States and Canada. Ideal for high-volume pharmacies needing automation and fast processing.

- Efficient & High-Speed: Packages up to 80 doses per minute with reduced material waste and downtime.

- Compact & Modular: Saves space with a smaller footprint and modular subassembly design for flexible upgrades.

- User-Friendly: Front-loading, simple interface, and intuitive maintenance reduce training and operator workload.

- Cost-Saving: Customizable pouch sizes and energy-saving modes reduce material and power costs.

- Safe & Reliable: Built-in sensors, clear visibility, and controlled access reduce errors and improve operator safety.

- Ready to Use: Minimal setup required with included tools and easy installation.

Technical Specifications

- Size: 25″ L x 11″ W x 11″ H

- Weight: 55 lbs.

- Power: 115 VAC 60 Hz, 200 VA or 230 VAC 50 Hz, 200 VA

- Sealing Temp: Available setpoints are from 80°C to 130°C. The default temperature is 105°C

- Hardware Requirements: Windows® 10+, 10 GB hard drive, 8 GB RAM, USB ports, printer, Internet access.

- Material Requirements: Requires MPI-authorized disposable materials.

- Space Requirements: Countertop height: 28″-36″; clearance: 18″-24″; minimum counter depth: 18″; counter space: 4′-5′ to allow for PC attachment.

- Electronic Components: Requires two 120V outlets.

- Barcodes Supported: All linear and 2D barcodes.

- Chutes/Disks: Comes with two pill chute sizes (1″ and 5/8″) and three feed disk sizes (1/2” round/tablet, 1″ round/tablet, 1″ oblong/capsule). Additional sizes available.

- Barcode Verifier Option: Ensures barcode is readable for scanning before packaging completion.

Pak-EDGE® UD Barcode Labeling Software

- Exclusive MPI software for Auto-PrintTM Plus.

- Windows®-based with optional First Databank access.

- Accommodates all linear, 2D, and GS1 barcodes.

- Unlimited barcode configurations including:

- Product NDC code

- Local expiration date

- Date packaged

Frequently Asked Questions

Equipment & Installation

Q: What space requirements does the pill packaging machine have?

A: The Auto-PrintTM packaging machine requires a sturdy countertop 28-36 inches high with 18-inch depth and 4-5 feet of length. The equipment needs two 120V outlets and clearance of 18-24 inches above the counter. This compact design fits most existing pharmacy production

Q: What production capacity can I expect from the packaging system?

A: The packaging machine provides 4 different speed options allowing users to produce 50-80 packages per minute. This high speed production capacity eliminates manual packaging process bottlenecks and significantly improves pharmaceutical packaging efficiency.

Q: Does the machine meet GMP requirements for pharmaceutical manufacturing?

A: Absolutely. Our products are consistently produced and controlled according to quality standards. All materials are compliant with FDA regulations and meet USP standards for pharmaceutical packaging. Our quality control systems support regulatory inspections and documentation requirements.

Q: Can the machine package both tablets and liquid products?

A: The Auto-PrintTM Plus specializes in oral solid medication including tablets and capsules. For liquid product packaging, MPI offers separate filling machine solutions like the Fluidose system. Our main products line covers both solid and liquid pharmaceutical packaging needs.

Q: What materials does the packaging process require?

A: The packaging machine uses MPI-certified consumable materials including SUPERTHERM® thermal paper, SUPERCEL® film, and SUPERFOIL® for moisture-sensitive medication. These materials meet industry standards and FDA requirements for packaging.

Contact MPI Today for Personal Assistance

Ready to eliminate manual packaging inefficiencies and enhance patient safety? Medical Packaging Inc.’s Auto-PrintTM pill packaging machine delivers the advanced technology and reliability your pharmaceutical packaging operation needs.

With over 50 years experience serving the pharmaceutical industry, MPI provides proven packaging systems that integrate with your existing workflows while meeting GMP requirements and regulatory standards.

Contact Medical Packaging Inc. today to discover how our pharmaceutical packaging equipment can transform your medication packaging operations and deliver measurable improvements in efficiency, compliance, and patient care.

Experience reliable pharmaceutical packaging machinery designed for modern healthcare operations.