Pharmaceutical Supply Chain Management: Key Steps & Challenges

Supply chain disruptions have significantly impacted many industries, with the pharmaceutical sector experiencing challenges that affect patient care and public health. Recent analysis indicates that proposed pharmaceutical tariffs could further worsen these issues, as over 50% of drugs used in the U.S. are manufactured abroad, and tariffs ranging from 50% to 200% could disrupt an already fragile global supply chain. Any disturbance in this process can negatively affect patient safety and the healthcare industry.

Understanding the key steps involved in the end-to-end supply chain is crucial for pharmaceutical companies and drug manufacturers in the United States. By gaining this insight, industry leaders can develop effective solutions to mitigate supply chain issues and ensure a steady flow of essential medications, from generic medicines to specialty prescription drugs.

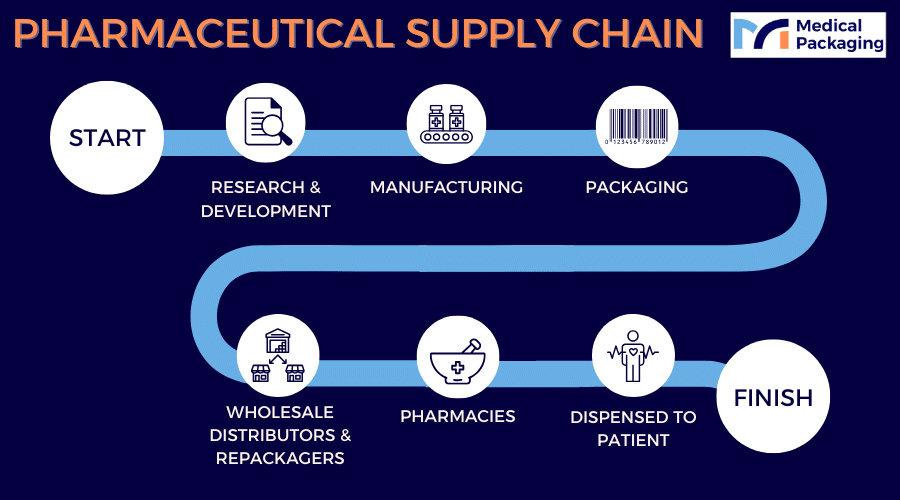

The pharma supply chain begins with the research and development process and ends with medication dispensing to consumers. This network involves multiple stakeholders who play a significant role in ensuring medication accessibility and safety:

- Drug manufacturers and pharmaceutical manufacturers

- Packaging companies serving the pharma industry

- Regulatory agencies including the Food and Drug Administration (FDA)

- Wholesale distributors

- Healthcare providers and healthcare systems

- Pharmacy benefit managers

- Insurance companies and health plans

- Specialty pharmacy operations

The supply chain process contains several steps that are aimed at ensuring patient safety while addressing customer demand across diverse healthcare markets.

Key Players in the Pharmaceutical Supply Chain

The pharma supply chain begins with the research and development process and ends with medication dispensing to consumers. This network involves multiple stakeholders who play a significant role in ensuring medication accessibility and safety:

- Drug manufacturers and pharmaceutical manufacturers

- Packaging companies serving the pharma industry

- Regulatory agencies including the Food and Drug Administration (FDA)

- Wholesale distributors

- Healthcare providers and healthcare systems

- Pharmacy benefit managers

- Insurance companies and health plans

- Specialty pharmacy operations

The supply chain process contains several steps that are aimed at ensuring patient safety while addressing customer demand across diverse healthcare markets.

Key Steps Within the Pharmaceutical Supply Chain

The supply chain in the pharmaceutical industry is a complex process due to regulations, safety requirements, and excessive costs. Overall, each step in the process works to provide individuals access to safe pharmaceutical products, including generic drugs and prescription drugs, while maintaining supply chain visibility.

Research and Development

The first step in the pharmaceutical supply chain is Research and Development (R&D), where new drugs are discovered and developed. This process involves identifying potential compounds and conducting initial tests to assess their safety and effectiveness. Successful candidates then move on to clinical trials with human participants. Throughout this phase, regulatory agencies ensure that safety and efficacy standards are met before granting regulatory approval.

Manufacturing

Pharmaceutical manufacturing represents a critical phase where drug manufacturers must secure approval from federal agencies, such as the FDA, before they are allowed to manufacture over-the-counter or prescription drugs for consumers and patients. The pharma company utilizes raw materials, including active pharmaceutical ingredients, innovative technology, equipment, and supplies to produce different forms of medications. This includes:

- Tablets

- Capsules

- Liquids

- Creams

- Ointments

- Aerosols

Domestic production capacity has become increasingly important for national security, particularly following supply chain disruptions that highlighted potential risks in global supply chains.

Packaging

Packaging is a key step throughout the pharmaceutical process. Pharmaceutical packaging refers to the materials, designs, and systems that package, store, label, and help distribute medications to their next destination. Medications must be placed in packaging that meets strict regulations including those set by the FDA. Packaging must also protect products from damage, such as exposure to light or temperatures.

Effective systems and materials can provide real benefits to each key stakeholder in pharmaceutical supply chain management, including:

- Reduction of medication errors

- Protection of valuable products

- Compliance with regulatory authorities

- Enhanced traceability and supply chain visibility

- Cost reduction for the pharmaceutical company

Wholesale Distributors & Repackagers

Wholesale distributors or repackagers receive pharmaceutical products from drug manufacturing companies. Wholesale distributors purchase drugs from pharmaceutical manufacturers to store and distribute to healthcare markets. According to the Commonwealth Fund, about 92% of prescription drugs in the U.S. are distributed through wholesalers, making them essential players in the pharma supply chain.

A repackager will purchase large amounts of generic medicines and repackage the product into smaller quantities before reselling it in healthcare markets. Problems with this part of the supply chain, from staffing to equipment to raw material availability, can result in delays in pharmacies being able to obtain the medications they need to stock.

Pharmacies

Pharmacies are typically one of the last steps before the drug reaches the consumer. The specific process of distribution will differ depending on the type of pharmacy and the healthcare market where the pharmacy operates.

Whether in hospitals, acute care facilities, integrated delivery networks, long-term care facilities, or specialty markets, pharmacies must get the right medication to the right patient at the right time. Specialty pharmacy operations often require additional considerations for handling complex medications and medical devices.

Dispensed to Consumers

The last part of the supply chain is having medications dispensed to consumers. This might involve having consumers purchase prescription drugs from healthcare providers or pharmacies. In other cases, consumers can purchase over-the-counter medications from drugstores, supermarkets, department stores, and other retail businesses.

Healthcare providers work closely with insurance companies and health plans to ensure patient access to essential medications while managing costs across the system.

Addressing Challenges in the Pharmaceutical Supply Chain

The pharmaceutical supply chain faces several challenges, from drug shortages to increased drug costs. Taking a closer look at key challenges in the supply chain can help pharmaceutical manufacturers, packaging companies, distributors, and pharmacies determine efficient, cost-effective solutions.

Costs

The pharmaceutical supply chain can impact the cost of pharmaceutical products. Complexities within global supply chains can lead to higher costs for every stakeholder, including consumers. With over 85% of biopharma executives now investing in data, artificial intelligence, and digital tools to build supply chain resiliency, finding cost-effective solutions and innovative technology are key ways to simplify the supply chain and improve operational efficiency to help reduce the cost of medications and drug production.

Regulations

Companies and organizations that are part of the pharma supply chain often have multiple regulations to meet for safety purposes. Although these regulations are an important part of patient safety in the U.S., complying with them can result in delays or other issues that disrupt the supply chain. Recent regulatory developments have emphasized the importance of strengthening domestic pharmaceutical capabilities while ensuring continued access to medications.

Regulatory agencies have implemented various requirements that pharmaceutical companies must navigate, while executive orders have emphasized the importance of strengthening the pharmaceutical industrial base. Utilizing systems and partnerships that provide speed to market regulatory and technical support is one way to accelerate the regulatory approval process.

Safety & Security

Safety is the most important element of the supply chain and a cornerstone of public health protection. Drug manufacturing companies are required to ensure product safety and quality during the manufacturing process. Packaging solutions play a vital role in health systems to ensure that medications avoid contamination or medication errors.

Utilizing effective packaging and labeling solutions is key for pharmaceutical manufacturers, repackagers, wholesalers, and pharmacies to provide safe and traceable medications. This is particularly important when dealing with medical devices and complex pharmaceutical products.

Drug Shortages

Drug shortages are among the biggest supply chain challenges facing the pharmaceutical industry today, with the number reaching 277 active cases as of September 2024. Without adequate amounts of certain medications to meet customer and patient demands, consumers face difficulties in treating health issues. The most impacted drug categories include chemotherapy agents, central nervous system stimulants, antimicrobials, hormone therapies, and intravenous (IV) fluids. A drug shortage can significantly impact public health outcomes and strain healthcare providers.

According to the U.S. Pharmacopeia, the average duration of drug shortages has surpassed three years, up from approximately two years in 2020. Pharma companies that can find effective solutions to these shortages, as well as ways to prevent them from happening, can end up having a distinct competitive advantage over other drug manufacturers while better serving market share demands.

Why Drug Shortages Happen

Drug shortages in the U.S. or global supply chains can occur for many reasons:

- Problems with Manufacturing Quality: This is a leading cause of drug shortage and can potentially compromise patient safety. For example, a 2022 FDA inspection of a facility in India responsible for producing about half of the U.S. supply of the chemotherapy drug cisplatin revealed quality control issues, resulting in a nationwide shortage.

- Obtaining Raw Materials: Pharmaceutical manufacturers sometimes face difficulties in obtaining the raw materials needed for production. For example, production may be delayed if the active pharmaceutical ingredient is unavailable.

- Limited Production Capacity: Supply shortages can also occur due to limited production capacity or drug discontinuation.

- Increased Demand: Sudden spikes in customer demand, often due to health crises or seasonal illnesses, can outstrip the supply of certain medications. ADHD medications and GLP-1 drugs for weight loss have been in particularly short supply due to rising usage.

- Supply Chain Disruption: Natural disasters can create significant disruptions. Hurricane Helene’s impact on a key North Carolina facility exacerbated IV fluid shortages affecting hospitals nationwide.

- National Security Concerns: Dependence on overseas manufacturing has raised concerns about domestic production capabilities, with over 50% of drugs used in the U.S. manufactured abroad.

A recent case study of pharmaceutical supply chain challenges highlighted how private sector and public health agencies must work together to address these complex issues.

Pharmaceutical Supply Chain Priorities

Although some supply chain disruptions are difficult to prevent, working toward greater efficiency overall can help minimize their negative impact. Recent priorities from U.S. health service providers and pharma industry executives to improve the supply chain include enhanced supply chain visibility and stronger partnerships between the private sector and human services agencies.

The development of a national strategy for pharmaceutical supply chain resilience has become a key focus, addressing potential risks and strengthening the overall industrial base. The American Medical Association has declared drug shortages to be an urgent public health crisis and a national security threat, emphasizing the critical need for coordinated solutions.

The Future of Supply Chain Management

The future of supply chain management in the pharma industry will be shaped by artificial intelligence and data analytics, driving digital transformation, and enhancing supply chain visibility. These technologies will optimize operations, reduce the carbon footprint, and ensure more efficient and transparent processes from production to delivery.

Industry leaders are increasingly focusing on building resilient supply chains that can withstand disruptions while maintaining access to essential medications and medical devices.

The Critical Role of Packaging in Pharmaceutical Supply Chain Transparency

Packaging plays a vital role in enhancing the transparency and security of the pharmaceutical supply chain, two main priorities outlined above. Packaging ensures that medications are protected from contamination and damage, preserving their efficacy and safety for patients. Clear and accurate labeling on packaging improves traceability, enabling stakeholders to track the journey of a drug from manufacturing to the end user with real-time visibility.

This transparency helps in identifying and addressing potential issues quickly, such as recalls or counterfeit products. Additionally, innovative packaging solutions provide added layers of security and real-time data, further strengthening the supply chain’s integrity. Key benefits include:

- Tamper-Evident Seals: Protect products from unauthorized access

- Smart Packaging with Embedded Technology: Offers real-time visibility and tracking data

- Enhanced Security: Reduces the risk of counterfeit products

- Improved Compliance: Supports pharmaceutical companies in meeting regulatory requirements

MPI Packaging Solutions for Improved Inventory Management

Medical Packaging Inc., LLC (MPI) offers effective unit dose packaging solutions for key stakeholders in the pharmaceutical industry. These solutions include different types of packaging systems and materials that are designed to improve safety, promote efficiency, and reduce costs in pharmaceutical supply chain management.

Our offerings include oral solid packaging systems, labeling solutions, overwrapping systems, oral liquid packaging systems, medical packaging materials, and more. These solutions support pharmaceutical manufacturers, specialty pharmacy operations, and healthcare providers in maintaining efficient supply chain operations.

Our completion of a Type III Drug Master File (DMF) submission to the U.S. Food & Drug Administration (FDA) allows us to ensure a rapid response to customers’ compliance and filing needs within the pharmaceutical industry. It also helps us meet the needs of pharmaceutical drug manufacturers and contract drug manufacturing organizations (CDMOs) for FDA-compliant liquid cup packaging capabilities.

By partnering with MPI, pharmaceutical companies can enhance their supply chain visibility, reduce potential risks, and better serve customer demand across diverse healthcare markets.

Resources

“The Impact of Pharmaceutical Wholesalers on U.S. Drug Spending.” Commonwealth Fund, 20 July 2022.

“The current state of U.S. drug shortages.” Maxor, 30 Jan. 2025.

“Drug shortage update: How 2025’s drug supply chain is evolving.” Maxor, 23 Apr. 2025.

“U.S. drug shortages reach decade-high and last longer.” U.S. Pharmacopeia, accessed from https://www.usp.org/news/us-drug-shortages-reach-decade-high-and-last-longer.

“The cisplatin shortage: How one plant inspection triggered a cancer drug crisis.” NBC News, accessed from https://www.nbcnews.com/specials/cisplatin-shortage-cancer-drug-chemotherapy-us/index.html.

“Hurricane Helene: Baxter’s manufacturing recovery in North Carolina.” U.S. Food and Drug Administration, accessed from https://www.fda.gov/drugs/updates-2024-hurricane-season/hurricane-helene-baxters-manufacturing-recovery-north-carolina.

Contact MPI Today for Personal Assistance

MPI’s Drug Master File provides speed-to-market regulatory and technical support related to our packaging components for medical and pharmaceutical market clients. Our solutions help pharmaceutical manufacturers navigate supply chain challenges while maintaining compliance and operational efficiency.

Content

- Key Players in the Pharmaceutical Supply Chain

- Key Steps Within the Pharmaceutical Supply Chain

- Addressing Challenges in the Pharmaceutical Supply Chain

- Why Drug Shortages Happen

- Pharmaceutical Supply Chain Priorities

- The Future of Supply Chain Management

- The Critical Role of Packaging in Pharmaceutical Supply Chain Transparency

- Resources

Contact MPI Today for Personal Assistance

MPI’s Drug Master File provides speed-to-market regulatory and technical support related to our packaging components for medical and pharmaceutical market clients