Prepackaging: The Smart Way to Manage Medications in Long-Term Care Facilities

Prepackaging: The Smart Way to Manage Medications in Long-Term Care Facilities

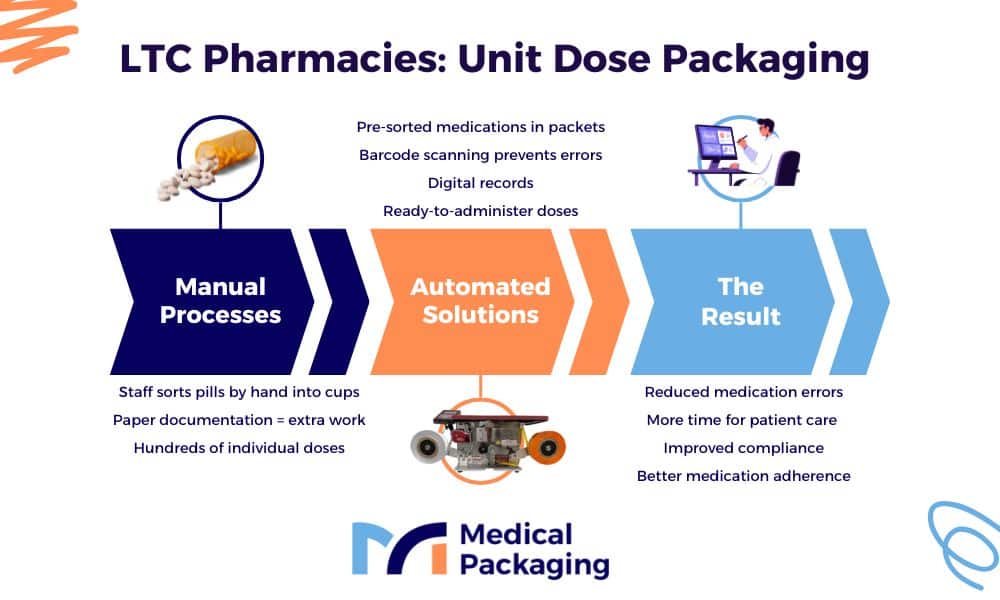

Managing medications in long-term care has never been more complex. With growing patient loads, staff shortages, and strict compliance requirements, traditional manual dispensing simply can’t keep up. That’s why more pharmacies are turning to prepackaged medication solutions: automated systems that improve accuracy, save time, and reduce costly medication errors. By shifting from manual sorting to unit dose packaging, long-term care pharmacies can streamline operations, ensure safer medication management, and free up staff to focus on patient care.

The Evolution of Medication Management in Long Term Care

Prepackaged medications and compliance pack solutions have replaced traditional manual prescription sorting in long-term care facilities, reducing medication errors and saving staff time. This technological upgrade allows facilities to meet increased patient care demands while improving medication adherence and documentation for seniors with complex medication routines.

Traditional Manual Processes

Traditional medication management in long-term care facilities relied heavily on time-consuming manual processes that increased the risk of errors:

- Nursing staff spent hours manually sorting medications into patient cups

- Bulk prescription medications from prescription bottles required extensive organization and verification

- Paper-based documentation created additional work

- Single unit dose passes involved hundreds of doses

- Staff dedicated entire shifts to medication preparation

- Healthcare providers struggled to manage individual needs for each patient

Industry Pressures Driving Change

Multiple converging factors have created an urgent need for improved medication management systems in long-term care:

- Growing seniors population increasing facility occupancy

- Ongoing healthcare provider shortages

- Stricter regulatory requirements for documentation

- Higher standards for patient safety

- Need for better medication management systems

- Rising medication non-adherence among older adults with cognitive impairment

Modern Packaging Technology Solutions

Today’s automated packaging systems address these challenges through advanced technology features:

- Automated sorting and blister pack systems

- Individual unit dose medications in sealed, labeled packages

- Multiple automated verification steps ensuring the right dose at the right time

- Barcode scanning capabilities for correct medication verification

- High-resolution imaging for error detection

- Bubble pack and pill pack formats for easy administration

Digital Integration Benefits

Modern prepackaged medication solutions integrate seamlessly with existing healthcare infrastructure:

- Connection with electronic health records

- Automated documentation trails

- Real-time inventory management tracking

- Automated production scheduling

- Reduced medication waste

- Improved regulatory compliance

- Simplified medication refill processes

This advancement in medication packaging technology represents a meaningful improvement from past manual methods, allowing long-term care facilities to focus more resources on patient care while maintaining accurate medication regimen management for residents with chronic conditions.

A old woman thinking with psychologist in consultation office for mind, evaluation or assessment.

Safety and Accuracy Advantages

Multiple Verification Systems

Pre-packaged doses and unit dose systems reduce medication errors through automated safeguards and verification systems. Barcode technology like Pak-EDGE® software enables precise scanning at every step of the medication journey, from packaging to dispensing, creating checkpoints that catch potential errors before reaching patients. Modern compliance packaging systems use high-resolution cameras and weight verification to confirm each prescription medication matches the prescribed order, ensuring the correct medication is delivered.

Clear Medication Organization

The structure of blister pack medications brings clarity that manual systems cannot match. Each dose arrives in marked packaging with large, readable text showing the correct medication, strength, and right time for administration. This organized approach removes confusion from similar-looking medications or unclear handwriting that often cause medication errors in traditional dispensing methods using pill bottles. This is particularly important for older adults who may struggle with complex regimens or have cognitive impairment.

Digital Tracking and Documentation

Digital inventory management provides detailed oversight of medication tracking and usage. Pre-packaged doses automatically log lot numbers and expiration dates while monitoring prescription quantities. This digital documentation creates a complete record of every medication’s path through the pharmacy, supporting regulatory compliance and quality control while reducing additional cost associated with waste.

Simplified Staff Workflow

The verification process builds patient safety while reducing pressure on staff. Instead of counting pills or checking multiple references, healthcare providers can verify accuracy through automated systems. This reduces manual handling time and decreases chances for human error. The system keeps electronic records of medication management, maintaining accountability throughout the process and ensuring patients receive the right dose of prescription drugs.

Measurable Safety Results

These technology advances lead to concrete improvements in medication adherence and patient outcomes. Studies show that medication-related error rates in long-term care facilities range between 16-27% of residents, with serious complications occurring in up to one in ten medication errors. When paired with staff training and consistent processes, prepackaged medications help long-term care facilities maintain high standards in patient care while protecting staff and residents from preventable harm.

Operational Benefits and Cost Savings

Time Management Improvements

Long-term care facilities that switch to compliance packaging and prepackaged medications experience significant operational advantages that directly impact their bottom line. Automated unit dose systems can produce 55-80 packages per minute, dramatically reducing medication preparation time compared to manual processes.

Time management improvements have become a standout benefit for facilities using prescription medications in blister packs:

- Reduced manual sorting: Pharmacy staff no longer spend hours manually sorting and packaging medications from pill bottles, as pre-packaged doses arrive ready for administration

- Faster medication passes: Nurses can access clearly labeled unit dose packets instead of managing multiple prescription bottles

- Streamlined inventory: Prepackaged medications come with standardized tracking systems that monitor stock levels automatically

Financial Advantages

The financial benefits of prepackaged medication solutions are equally impressive:

- Lower labor costs: Healthcare providers spend significantly less time on medication preparation

- Reduced waste: Precise dosing and extended shelf life of sealed bubble packs minimize medication waste

- Space efficiency: Compliance packaging takes up less room than traditional pill bottles and eliminates the need for multiple storage solutions

- Fewer medical emergencies: Facilities avoid additional costs by reducing trips to the emergency room or hospital emergency department caused by medication errors or medication non-adherence

Enhanced Staff Satisfaction

Staff satisfaction levels improve dramatically after implementing medication management systems:

- Lower stress levels: The simplified process reduces cognitive load and potential errors

- More time for patient care: Healthcare professionals can focus on residents’ individual needs and treatment plans

- Professional development: Staff members gain opportunities to develop new skills in medication routine technology while better serving seniors and family members

Implementing Modern Packaging Solutions with MPI

nit dose packaging systems deliver tangible benefits for long-term care pharmacies, including fewer medication errors, enhanced staff efficiency, and improved patient outcomes. The transition process typically involves analyzing current medication management workflow patterns, selecting appropriate unit dose packaging systems, training pharmacy staff, and implementing new procedures gradually across departments.

Looking ahead, prescription medication management continues to move toward greater automation and integration with electronic health records. The growing senior population and increasing complexity of medication regimens—with older adults often managing multiple chronic conditions and numerous prescription drugs—make now the perfect time to upgrade your pharmacy operations.

Medical Packaging Inc. (MPI) specializes in comprehensive pharmaceutical packaging and labeling solutions designed to improve efficiency and patient safety in long-term care settings. Whether your facility handles high-volume operations or specialized medication regimens for patients with complex chronic conditions, our unique product line will make the difference:

- Auto-Print® systems – Precise unit dose packaging for oral solids

- Fluidose® systems – Oral liquid medications packaged in unit dose cups with accuracy and compliance

- Pak-EDGE® UD Barcode Labeling Software – Integrated verification methods, drug library & inventory management, and regulatory compliance

Contact MPI to learn more about how our unit dose packaging solutions can transform your long-term care pharmacy operations. Our team will provide a customized assessment of your medication management needs and help you select the optimal packaging system for your facility.

Contact MPI Today for Personal Assistance

MPI’s Drug Master File provides speed-to-market regulatory and technical support related to our packaging components for medical and pharmaceutical market clients