Optimizing the Biopharmaceutical Manufacturing Process

Biological medical products, also known as biologics, or biopharmaceuticals, are being developed at a fast pace due to the consistently increasing demand throughout the healthcare industry.

According to The National Center for Biotechnology Information (NCBI), biopharmaceuticals refer to “pharmaceuticals produced in biotechnological processes using molecular biology methods.” This is opposed to the chemical synthesis process that is used in traditional pharmaceutical manufacturing, which focuses on active pharmaceutical ingredients and efficiency within a biopharmaceutical manufacturing facility.

Biotech vs Pharma

Biotechnology involves the use of technology and living organisms or other biological systems to create medicines, foods, or other products. Biotech is used for therapeutic proteins, gene therapy, and other types of medicinal products. It is also used for other purposes, such as agricultural, environmental, and industrial. Innovations like single-use technologies and advancements in cell therapy play a significant role in driving workforce development and improving processes within the biotech industry.

The pharmaceutical industry develops and produces medicines used for disease prevention and treatment, as well as prevention and treatment for other medical conditions. Standard pharmaceutical manufacturing typically uses chemical synthesis to create medicine.

The NCBI compares the biopharmaceutical manufacturing industry to the synthetic process to outline some key differences between the two. These include “the nature of the product, the source of the active agent, bioequivalence criteria, identity, structure, manufacturing methods, composition, dosing, formulation, handling, intellectual property rights, legal regulations, and marketing.” Biopharmaceutical production often involves recombinant proteins and relies on quality assurance to meet strict regulatory compliance standards.

Biopharmaceutical Companies

Biopharmaceutical companies have an increasingly valuable role in the treatment and prevention of diseases in the United States and other countries. Their contributions include:

- Protein therapeutics: Providing targeted treatment options for various diseases.

- Vaccine manufacturing: Advancing immunization efforts to combat infectious diseases.

- Monoclonal antibody production: Creating highly specific therapies for conditions such as cancer and autoimmune disorders.

- Gene therapy: Offering innovative solutions for genetic disorders and other complex conditions.

- Other products: Delivering alternative treatments to traditional pharmaceutical products.

These innovations often result from collaborations with research institutions and industry partners, focused on enhancing manufacturing capacity and driving breakthroughs in biopharmaceutical production.

With some major distinctions throughout the development process, biopharmaceutical companies face different challenges that pertain specifically to the biopharmaceutical manufacturing process. Solutions to overcome these challenges differ for every step along the drug’s lifecycle, from discovery to clinical research to packaging. Public-private partnerships are becoming key opportunities for overcoming these obstacles and developing innovative approaches to human services.

Important Regulations for Biopharma

Biopharmaceutical Product Approval

The approval path for biotech in the United States involves submitting a Biologics License Application (BLA) to the Center for Biologics Evaluation and Research (CBER). The BLA for each biologics product must be approved by the CBER.

This regulatory process for biopharmaceuticals is an important part of ensuring that products are safe before entering the market. Regulatory compliance is a cornerstone of this process, requiring rigorous documentation and adherence to a robust regulatory framework.

Pharmaceutical Product Approval

The approval path for traditional pharmaceutical products involves submitting a New Drug Application (NDA) through the FDA’s Center for Drug Evaluation and Research (CDER). The NDA includes test results for the product, manufacturing information, data from clinical trials, and a proposed label with information on the reason for use, how to use it, and potential risks.

If the product’s benefits outweigh any known risks, the regulatory agency approves it for commercial manufacturing. These stringent guidelines help maintain quality assurance throughout the process.

DSCSA and Supply Chain Traceability

Applying to every drug, whether developed synthetically or naturally, the Drug Supply Chain Security Act (DSCSA) was created in the United States to improve traceability in the supply chain for pharmaceutical products. This act has several provisions that are aimed at making it easier to keep track of pharmaceutical products that enter the supply chain.

This helps reduce the risk of having patients or consumers end up with counterfeit drugs or medicines. Although the law was enacted in 2013, full DSCSA implementation is set to occur in 2025, causing both pharmaceutical and biopharmaceutical companies to ask the question: Is our organization ready?

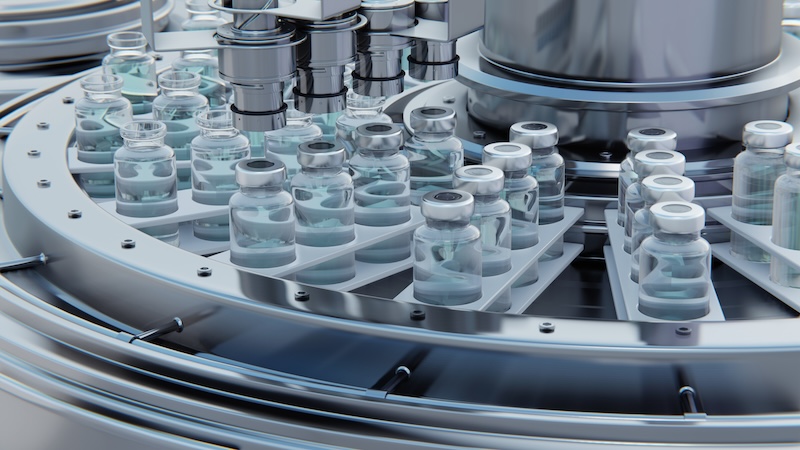

Biopharmaceutical Manufacturing Process

The biopharmaceutical manufacturing process is more complex than other processes used to make synthetic or traditional pharmaceutical products. For biologics, process development involves having to obtain, grow, or reproduce living organisms, such as bacteria or cells, in order to create medicinal products.

Working with living organisms rather than chemicals or other synthetic materials results in certain challenges in ensuring safety, quality, and efficacy. This complexity highlights the need for innovation in production facility designs and the use of innovative technologies.

Biopharmaceutical Packaging: Optimizing the Process

The packaging process is a significant part of these challenges since biologics products need to remain in good condition until they are administered. These types of medicine are usually injected rather than taken in oral form or used in topical form. Unlike traditional pharmaceutical medicines, biopharmaceuticals are much more sensitive to temperature changes and environmental factors. Ensuring raw materials and finished products are safely handled is critical.

Finding ways to optimize the biopharmaceutical packaging process can help biopharmaceutical companies reduce costs and keep their products in good condition.

Key Challenges in Manufacturing Biologics

Manufacturing biopharmaceuticals requires more complicated processes. The living organisms and biotechnology used for these products create challenges that make it difficult to produce, store, package, and transport them. This can lead to biologics that are deemed unsafe, ineffective, or unsuitable for use once they reach healthcare facilities or pharmacies.

Knowing more about these challenges can help companies find solutions for managing them, and optimizing the biopharmaceutical manufacturing and packaging processes overall.

Innovative Packaging Solutions to Meet Biopharma’s Unique Needs

Medical Packaging Inc., (MPI) has years of experience providing high-quality, dependable packaging solutions for pharmaceutical products. This experience has allowed our company to develop effective solutions that help ensure medicinal products maintain their efficacy and are safe to use after being packaged and shipped to healthcare facilities or pharmacies.

This expertise extends to the biopharmaceutical industry with its unique needs and challenges. Our packaging solutions can help ensure that biopharma products avoid contamination and damage during storage and transportation. Our systems also contribute to overall operational efficiency and reduce medication errors. These solutions can help offset the high cost of producing biopharma products while ensuring that these products remain safe for use.

MPI Products for Biopharma

At MPI, we offer packaging solutions aimed at meeting the challenges of storing and transporting biopharma products. Our oral liquid packaging products provide comprehensive solutions to many liquid biopharmaceutical packaging requirements. Alongside our products, MPI’s Drug Master File (DMF) provides speed-to-market regulatory and technical support, helping our customers through the approval process in a shorter time period.

The biopharma industry includes many products that are in the early stages of development. These products do not require large-volume manufacturing or packaging. Our cost-effective packaging solutions for specialty pharma manufacturers and repackagers ensure fast and efficient packaging that helps support the development and validation process.

Liquid Medication Solutions

MPI offers an innovative solution for liquid medications. Our FD-Pharma Unit Dose Packaging System provides barcode packaging that ensures precise dosing for oral liquid medications. This cost-effective solution is suitable for clinical trials, validation runs, and low-volume production, as well as full production. FD-Pharma is a printing and pumping system for use with our MPI-certified packaging materials that meet FDA regulations.

Fluidose® Series 6

The Fluidose Series 6 Unit Dose Packaging System from MPI is another barcoding packaging solution for liquid medications. This solution has a built-in syringe pump mechanism and can produce up to 22 doses per minute. Fluidose meets the Joint Commission’s regulations for dispensing liquid medications and includes our Pak-EDGE UD Barcode Labeling Software.

Contact MPI for More Information on Our Biopharmaceutical Packaging Solutions!

If you are looking for more information on solutions for optimizing biopharmaceutical manufacturing and packaging, please contact MPI. Our team of experts is happy to help you find the best packaging solution for your unique organization and market.

Resources:

Contact MPI Today for Personal Assistance

MPI’s Drug Master File provides speed-to-market regulatory and technical support related to our packaging components for medical and pharmaceutical market clients