Understanding The Unit Dose Supply Method

“Unit dose packaging involves enclosing individual doses of medication in separate, single-use packages to ensure precise dosing and maintain drug integrity.”

Every person is unique, as are their symptoms and illness. Therefore, distinct types of therapy, customized to each patient’s specific needs, are a necessary part of quality patient care.

Drug administration is a high-risk practice in and of itself. Aside from that, medical personnel in healthcare facilities are under extreme time constraints. Regardless, the only thing that matters, in the end, is that the appropriate drug at the proper dosage reaches the right patient at the right time. As a result, using the unit dose supply method helps hospitals reduce medication mistakes while also saving time for patient care.

Enhanced Patient Safety

The single-dose packaging method delivers the recommended dose of a given medicine to a specific patient at a particular time. It differs from previous approaches in that each dose of prescription medicine is packaged separately in a ready-to-administer form.

Each unit dose container is labeled so that it can be identified until it is administered to the patient. The packaging, which has a label showing detailed information, including the drug name, strength, control number, and expiration date, minimizes contamination caused by the drug’s transfer and handling. As a result, this patient medication package approach significantly decreases the possibility of medication errors.

The unit dose method offers multiple advantages:

- Improved drug control and monitoring of drug usage.

- Reduction in credits for medications

- Pharmacists have more influence over work habits and schedules.

- Patient medication profiles can be kept at the pharmacy for each patient so that pharmacists may participate in patient care monitoring.

- Improved utilization of pharmaceutical and hospital staff.

- The pharmacy prepares all medicine dosages necessary, giving pharmacists and nurses more time to provide direct patient care.

- Because the number of drugs is limited to the patient’s needs for 24 hours only, there is less pilferage and drug waste.

- Lowers revenue losses.

- Floor stock decreases in size.

- More accurate medication billing for patients. Patients are only charged for the exact drug products that are provided to them, adding a layer of convenience.

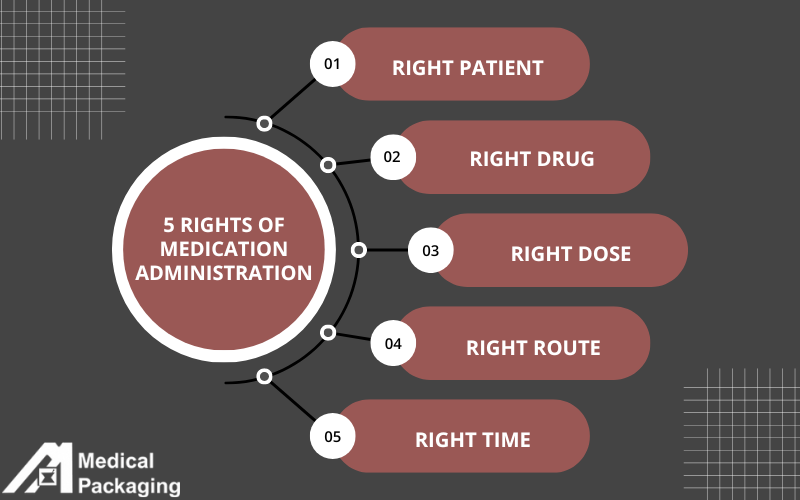

It is a system that supports the five rights of medication administration:

- Right patient

- Right drug

- Right dose

- Right route

- Right time

Planning a unit dose system is an uncomplicated process that can be done without interrupting the pharmacy operation or impacting patient care.

Identify Medications to Package in Unit Dose Form

The process starts with the hospital identifying all medications for use as a single unit dose and determining the form of packaging needed. The unit dose method is best suited for medications that come in bulk packaging.

However, most other types of drug packaging, such as suppositories, ampoules, transdermal patches, or prefilled syringes, can be packaged into unit dosages. After creating a unit medicine dosage, the oral solids or liquids can be ordered from the hospital pharmacy for safe medication administration.

One significant advantage of unit dosages is that the pharmaceuticals are not removed from the unit dose package until they reach the patient. This also implies no cross-contamination with other medications or human contact.

Unit dosages can also be used to develop a patient-specific treatment that incorporates more than one medicine. The medications are delivered to the nursing stations in patient-specific treatment carriers. This approach drastically reduces the time nursing personnel spend physically storing, sorting, and providing medicine. Furthermore, clear labeling of medicine, dose, batch, and expiration date improves safety in handling high-risk medication. The use of barcoded unit dose products and scanning procedures also helps with drug identification.

Facility Considerations

Type of Packaging Option for Each Medication

After the health care facility determines which medications are best suited for this unit dose supply method, and the ideal delivery method necessary for each, they must go through a system selection process that includes identifying the necessary equipment.

When identifying equipment requirements, include packaging equipment for the various dosage forms of medications such as tablets, capsules, injectables, and liquids. Other considerations include:

- Floor carts for direct distribution

- Modular filling stations

- Patient profile holders

Another critical decision to make is to decide what items should be purchased in unit dose packages, what is best for in-house repackaging, and how that is accomplished. This will involve identifying the unique package requirements, what supplies the pharmacy needs, and what volume is necessary for each format.

Unit Dose Budgeting

When budgeting for the unit dose supply method, the administration must determine the cost of the equipment and consumable supplies and the potential return on investment. How much is implementing this system saving the hospital?

Implementation and Training Considerations

Also, consider the impact the implementation of unit dose packaging will have on the staff and patient care workflow. How will it affect different pharmacy or hospital settings? The impact will be different in the pediatric wards than in the areas that deal primarily with adult patients, such as an acute care facility.

The administration will also need to consider training periods when planning implementation. Training will start in the pharmacy and then move to the medical and nursing units. Training can be conducted in a way that will not disrupt patient care.

Some efficient training approaches might include:

- Rotating pharmacy staff to work on the single dose dispensing every week until everyone goes through the training process

- Rotating the nurses through audiovisual presentations of the new system

- Providing general staff with information on the drug administration changes via newsletters or media

Training small groups at a time is the most effective way to avoid interruptions in patient care while still ensuring all employees understand the unit dose supply method.

At Medical Packaging Inc., LLC (MPI), we work with clients to support them not just when they are first establishing their unit dose system program but throughout training to implementation to utilization.

Establish Internal Planning for All Unit Dose Packaged Medications

The unit dose supply method requires careful planning before implementation beyond equipment, supplies, and training. In addition, protocols for dose preparation need to follow safe medication practices closely.

The healthcare facility will also need to have a system in place for storage, whether it is in a bulk storage space or on a cart in the nursing unit. There must also be plans for internal flow from patient admission to patient care area to patient medication profile to packaging to filling drug delivery carts.

Some common considerations include:

- Setting up the ward stock procedures

- Designing stock batch controls

- Inventory tracking and management

- Determine how to manage drugs not used

There may also be a need to modify existing procedures and integrate current technology to support the new way of ordering and administering medication, along with how to do proper dose calculations and avoid medication errors.

Additional Pharmacy Requirements to Review

Space Assessment

Conduct a space assessment to see how much room is available and decide how much extra space might be needed. A centralized pharmaceutical storage system with a pharmacy automation solution is essential to allow medical professionals to deal with unit dosages throughout a healthcare facility.

Pharmacy System Reconfiguration

Nurses are liberated from repetitive chores and may dedicate more time to patient-related activities by centralizing drug storage and therapy preparation inside the central pharmacy. Selection and sorting mistakes that occur during the preparation of manual drug preparation are also eliminated. Therapies can be produced at any moment, whether planned or unplanned. The unit dosage drug and the therapeutic ring can also be manufactured at the same time.

It is necessary to ensure compliance with the Consumer Product Safety Commission and industry standards i.e. USP 800 and serialization. At the same time, healthcare facilities must implement safety protocols, QA standards, and testing.

However, the most critical aspect of implementing the unit dose supply method is partnering with the right company for equipment and packaging needs.

We are always developing our pharmacy packaging technologies to ensure continuing conformity to industry rules and regulatory requirements for unit dosage pharmaceutical packaging.

Future Unit Dose Packaging Trends

Unit dose packaging, especially in the pharmaceutical sector, is expected to see significant growth due to increasing demands for precise dosing and patient safety. Innovations in smart packaging technologies, like RFID and QR codes, will enhance medication adherence and tracking, making unit dose packages more interactive and informative. Additionally, the shift towards AI will become even more apparent in the coming months and years.

MPI's Role in Unit Dose Packaging

Medical Packaging Inc., LLC was founded in 1971 and has since evolved to become one of the world’s top unit dosage packaging system manufacturers. We take pride in having an accepted Drug Master File (DMF), producing high-quality pharmaceutical packaging equipment, MPI-certified consumable materials, and our proprietary Pak-EDGE UD Barcode Labeling Software.

MPI, headquartered in the United States in Flemington, New Jersey, services customers in North America, Latin and South America, Europe, the Middle East, and emerging countries across the world. MPI aims to be the leading provider of pharmacy packaging solutions that help save patients’ lives while boosting productivity and profitability for all clients.

We provide high-quality items at reasonable costs, and our equipment offers the most up-to-date features and functionality while preserving optimum dependability and simplicity of use. All our clients receive prompt, professional, and courteous customer service and technical assistance. We establish, maintain, and promote continuing connections with our customers, strategic partners, and distributors alike, based on a foundation of professionalism and excellence.

Contact us or request a quote to learn more!

Resources

“NFC vs. QR Codes: Everything You Need to Know.” atlasRFIDstore, www.atlasrfidstore.com/rfid-insider/nfc-vs-qr-codes-everything-you-need-to-know/. Accessed 20 March. 2024.

Author links open overlay panelKeisheni Ganeson a, et al. “Smart Packaging − a Pragmatic Solution to Approach Sustainable Food Waste Management.” Food Packaging and Shelf Life, Elsevier, 7 Feb. 2023, www.sciencedirect.com/science/article/abs/pii/S2214289423000212.

Contact MPI Today for Personal Assistance

MPI’s Drug Master File provides speed-to-market regulatory and technical support related to our packaging components for medical and pharmaceutical market clients