Smart Packaging Technologies for Improving Medical Packaging

In the fast-paced consumer goods industry, one innovation is quietly reshaping how we think about packaging: Smart Packaging.

Smart packaging integrates science and technology to create packaging solutions that use digital identifiers to monitor product quality and track a package’s journey. Smart packaging of consumer goods is used in food and beverage, retail, automotive, electronics, and medical industries.

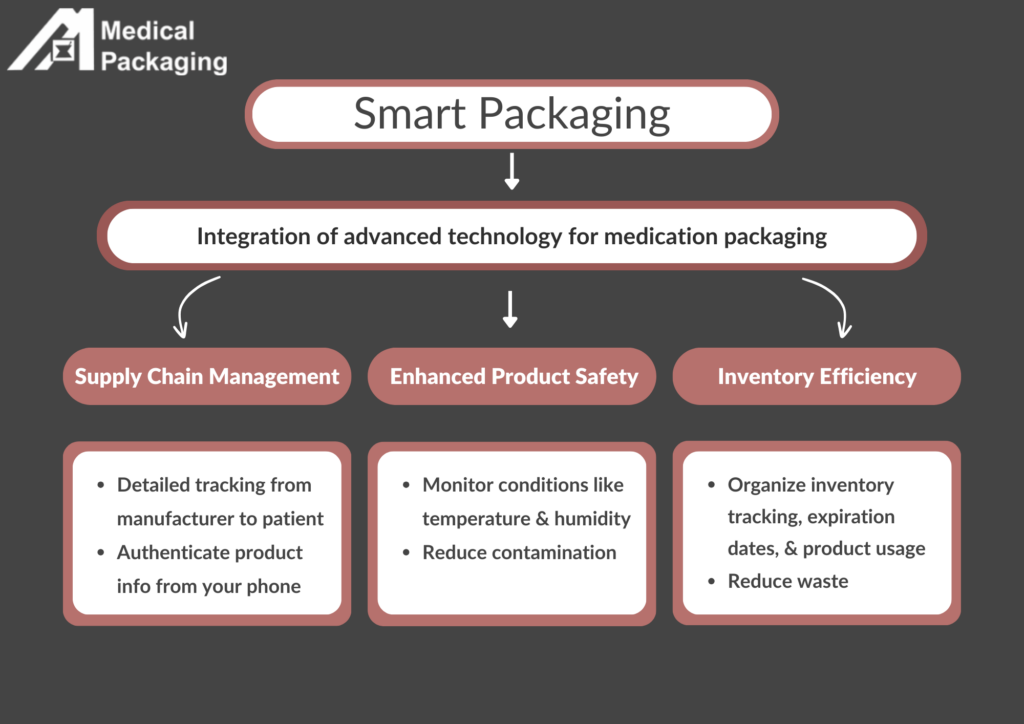

Benefits of Smart Packaging

Smart packaging systems offer many benefits and practical applications across the food safety and medical industry. From general traceability, cost savings, and environmental impact to more specific medication adherence improvement, smart packaging is revolutionizing packaging.

Improved Traceability and Transparency

Smart packaging solutions such as electronic microchips facilitate end-to-end traceability of products from manufacturing to consumption. This enables supply chain stakeholders to track product movement, authenticate products, and identify potential issues or bottlenecks, enhancing transparency and accountability.

Increased Efficiency and Cost Savings:

Smart product packaging streamlines various processes throughout the supply chain, from production and distribution to retail and consumption. Smart packaging helps pharmaceutical companies save time, reduce costs, and improve profitability by automating tasks, reducing manual errors, and optimizing resource utilization all through connected data management.

Sustainability and Environmental Impact

Smart packaging solutions can contribute to sustainability goals by reducing waste, minimizing packaging materials, and optimizing logistics processes. For example, intelligent packaging technologies help prevent medicine and food waste by extending shelf life and reducing spoilage, while also enabling eco-friendly packaging designs and smart materials for a reduced carbon footprint. Improved inventory tracking leads to reduced product wastage, thereby decreasing the necessity for excess production and packaging.

Medication Adherence

One of the significant challenges in medication management is ensuring adherence, especially for elderly or chronically ill patients, taking multiple medications. Intelligent packaging, with the help of RFID and NFC tags, can offer simple solutions to this complex problem. It provides a valuable customer experience by offering reminders, and dosage information while enabling real-time interaction with healthcare providers.

By harnessing the power of technology and innovation, smart packaging is reshaping industries and driving positive outcomes for companies and consumers alike.

The Evolution of Packaging in The Medical Industry

The healthcare industry has traditionally complex requirements for packaging—far beyond just containing a drug or medical device. Storage safety, compliance, patient convenience, and label clarity have always been a priority for medical packaging. In recent years, there has been a greater emphasis to improve:

Traditional packaging serves primarily as containment for the product and the medium for the product information. As healthcare moves towards precision and patient-centricity, the limitations of traditional packaging have become apparent. Traditional packaging cannot provide real-time data, engage with the patient, monitor product integrity, or facilitate traceability. Smart packaging, with its ability for connectivity and advanced functionality, has emerged as the solution to these challenges.

It uses technologies such as QR codes, NFC tags, RFID tags, intelligent indicators, and more, embedded in the package or label, to communicate with the user and the environment. The smart packaging solutions are apt for tracking the supply chain, enhancing patient engagement, improving medication adherence, and maintaining the product’s condition.

Primary Types of Smart Packaging

Within smart packaging, two primary categories differentiate technological capabilities: active and intelligent packaging. Active packaging interacts with the products within the package, while intelligent packaging monitors the packaging itself in different ways.

Active Packaging

Active packaging is an advancement in medical and food packaging that allows for an extended shelf life of the product and quality control. This is especially important for efficacy, patient safety, and quality assurance. According to The National Library of Medicine, active packaging has direct contact with the product and is designed to:

- Mitigate moisture

- Inhibit microbial growth

- Protect the product

Intelligent Packaging Systems

Intelligent labels encompass a broader category of packaging technologies that incorporate sensors, indicators, or electronic components to provide real-time information about the product’s condition or environment.

Smart labels serve various purposes, including product quality monitoring, tamper detection, and authentication.

Specific Smart Packaging Technologies

These new technologies have helped smart packaging evolve into the higher-level products they are today.

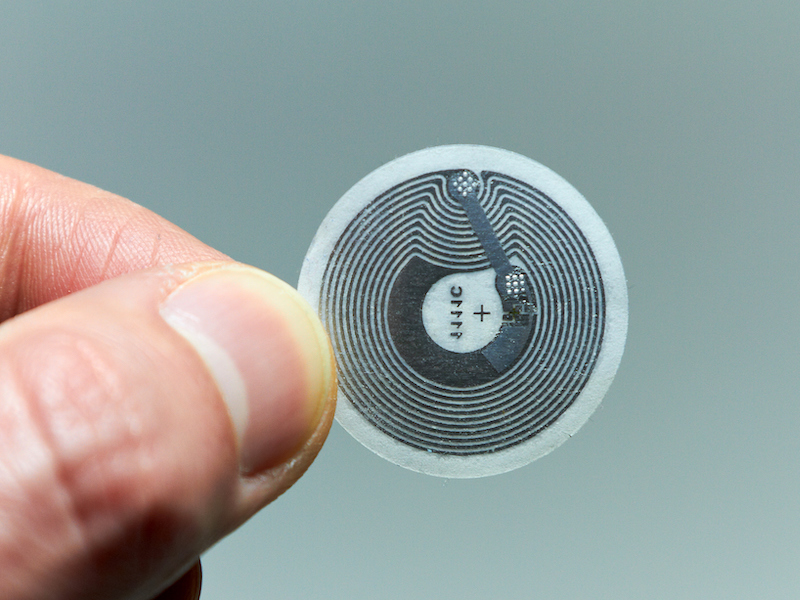

- Near Field Communication (NFC): NFC tags are small chips embedded in packaging that enable wireless communication with NFC-enabled smart devices like iPhones. Tapping a smartphone on NFC-enabled packaging gives patients instant access to product details and helps manufacturers in brand protection through product authentication and supply chain optimization.

- Radio Frequency Identification (RFID): RFID tags are small electronic devices that use radio waves to transmit data to RFID readers. These tags consist of an antenna and a microchip, which stores information about the tagged item. RFID tags offer several advantages in the packaging industry such as real-time tracking throughout the supply chain, inventory management, and anti-counterfeiting abilities.

- Time Temperature Indicators (TTIs): TTIs are a simple smart device that tracks the thermal history. They provide a visual indication of whether a product has been exposed to temperatures beyond a specified threshold for a certain duration, helping determine if the product is still safe or viable for use.

- Chemical Indicator Inks: Chemical indicator inks are substances designed to undergo a visible change when exposed to specific chemical conditions, such as temperature, pH, or the presence of particular gases. They are often used in packaging and industrial processes to indicate whether certain conditions, such as sterilization or chemical exposure, have been met or exceeded.

Barcodes: Convenient and Effective Smart Packaging Technology

Barcodes are essential to the future of the smart packaging market. Aside from their convenience and cost-effectiveness, they offer other benefits such as:

- Product identification: Barcodes provide a simple yet effective means of identifying medical products by encoding essential information such as product name, dosage, and expiration date.

- Inventory management: In healthcare settings, barcodes streamline inventory management processes by enabling quick and accurate tracking of stock levels, reducing the likelihood of stockouts and excess inventory.

- Patient safety: Barcodes enhance patient safety by ensuring that the right medication is administered to the right patient, minimizing the risk of medication errors and adverse drug events.

- Regulatory compliance: Barcodes facilitate compliance with regulatory requirements, such as FDA regulations for product labeling and tracking, helping healthcare providers meet stringent quality and safety standards.

- Workflow efficiency: By automating data capture and entry processes, barcodes improve workflow efficiency in medical facilities so healthcare professionals can focus more on patient care.

Continuous Improvement: Overcoming Smart Packaging Challenges

Despite its numerous benefits, smart packaging also has its limitations and challenges such as:

- Cost Implications: The initial cost of implementing smart packaging solutions can be prohibitive, particularly for small and medium-sized businesses. Investments in infrastructure, equipment, and training are required, adding to the overall expenses.

- Complexity Challenges: Pharmaceutical packaging companies may struggle with integrating and managing multiple smart packaging solutions simultaneously.

- Data Privacy Concerns: Collecting and transmitting sensitive information through smart packaging raises concerns about data privacy, security, and regulatory compliance. Having a plan to adhere to regulations and address these concerns is important.

Continued innovation and collaboration are crucial to overcoming these challenges for the future of smart packaging.

MPI: Offering Advanced Smart Packaging Technology

Having explored smart packaging in medicine, one thing stands clear – the future of medication packaging is smart, informed, and precise. No longer are we encased in the old model where the packaging was just a carrier and organizer. We are moving towards a model where packaging communicates, engages, and most importantly, serves as an active tool in improving patient care and outcomes.

We develop smart packaging solutions that cater to varying market sectors – from hospitals, acute care facilities, and extended care pharmacies to specialty pharma. We continually work to anticipate future challenges and opportunities.

Barcode Smart Packaging with MPI

We have developed a range of unit dose packaging machines and barcode labelers that facilitate the organization and help reduce medication errors. Our packaging systems come with the powerful yet easy-to-use Pak-EDGE® UD Barcode Labeling Software, simplifying the process of designing customized labels and barcodes.

With our proprietary barcode labeling software, MPI is proud to offer a single-user interface to all of our packaging and labeling systems, giving our customers the tools they need to get the most from their MPI equipment and packaging materials.

Our products are backed by our standard equipment warranty and expert assistance from our Customer Success and Technical Support Centers, ensuring long-lasting solutions and an excellent customer experience.

For more information on our smart packaging options, please contact us today!

Resources

Jiang, Yongli, et al. “Latest Advances in Active Materials for Food Packaging and Their Application.” Foods (Basel, Switzerland), U.S. National Library of Medicine, 7 Nov. 2023, www.ncbi.nlm.nih.gov/pmc/articles/PMC10670037/.

“NFC vs. QR Codes: Everything You Need to Know.” atlasRFIDstore, www.atlasrfidstore.com/rfid-insider/nfc-vs-qr-codes-everything-you-need-to-know/. Accessed 20 March. 2024.

Author links open overlay panelKeisheni Ganeson a, et al. “Smart Packaging − a Pragmatic Solution to Approach Sustainable Food Waste Management.” Food Packaging and Shelf Life, Elsevier, 7 Feb. 2023, www.sciencedirect.com/science/article/abs/pii/S2214289423000212.

Creative, Appetite. “Smart Packaging Opportunities and Challenges.” LinkedIn, 28 June 2023, www.linkedin.com/pulse/smart-packaging-opportunities-challenges-appetitecreative/.

Imgix, base.imgix.net/files/base/ebm/hpn/document/2020/12/2101_CEU.5fd7acaa6d97f.pdf. Accessed 18 Mar. 2024.

llisa, Author. “Everything You Need to Know about RFID Tags.” A Blog to Share Some Knowledge, 12 Feb. 2023, blogs.bu.edu/llisa/everything-you-need-to-know-about-rfid-tags/.

Content

- Benefits of Smart Packaging

- The Evolution of Packaging in The Medical Industry

- Primary Types of Smart Packaging

- Specific Smart Packaging Technologies

- Barcodes: Convenient and Effective Smart Packaging Technology

- Continuous Improvement: Overcoming Smart Packaging Challenges

- MPI: Offering Advanced Smart Packaging Technology

- Resources

Contact MPI Today for Personal Assistance

MPI’s Drug Master File provides speed-to-market regulatory and technical support related to our packaging components for medical and pharmaceutical market clients